Product & Technology

FOCUS TECHNOLOGY

Automotive Electronic Control Unit(ECU) Reliability Performance Tester

Our company is steadily supplying reliability and performance tester of about 30 species of automotive ECU applied on Car body

/ Power-Train / Chassis since 2001.

The main functions are introduced as below.

Automotive Electronic Control Unit (Automotive ECU)

Automotive Electronic Control Unit (Automotive ECU)

The present car serves to control most of the vehicle operation through electronic control unit(ECU). ECU controls the fuel consumption and output in accordance with situation by making different values depending on habits of driver, operating environments and driving conditions through self-learning functions even the same kind of car.

Early ECU was developed for the purpose of controlling key features such as ignition timing, fuel injection and idling before, however, now it is responsible for the control of various systems besides engine

Testing of Electronic Control Unit (ECU)

Testing of Electronic Control Unit (ECU)

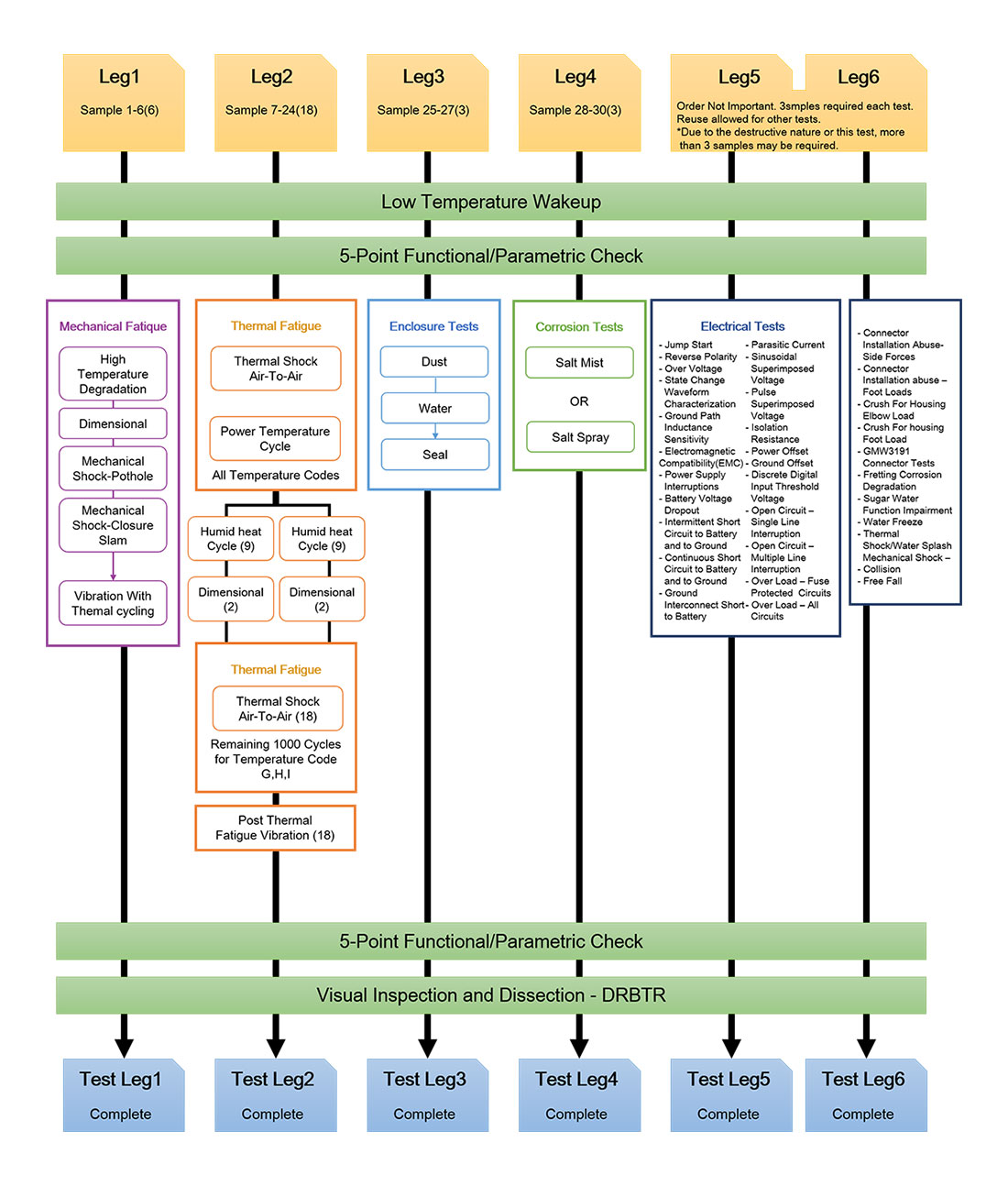

Automotive ECU is required to verify its reliability and durability in various environments and driving conditions. ECU has been tested based on manual tests on past products, but now it is configured to be able to test under the same conditions through computer-driven automatic test equipment. Testing ECU requires the following various tests.

- 01Performance test for electronic input/output control signal & entire functions.

- 02Mechanical durability test (high temperature, physical shock, vibration, etc

- 03Temperature durability test (temperature shock, temperature and humidity testing, etc.)

- 04 Enclosure durability Test (dust, waterproof, etc.)

- 05Corrosive Test (salt water injection, etc.)

- 06Electrical reliability Test (electric shock, overvoltage, voltage fluctuation, etc.)

- 07Connecter Durability Test (shock, environments, etc.)

Life-Time Tester

Life-Time Tester

ECU equipped on automotive should be able to operate without replacement during the life-time of cars. For testing ECU reliability, life time tester verifies ECU’s life-time through Accelerated life-time test conditions by setting maximum load condition and connecting input signal connected to ECU.

The Life Time Tester is configured to satisfy maximum load and maximum operating conditions of ECU and to be able to test failure mechanism or life-time distributions of ECU by connecting all input/output signals. The life-time tester is made up to test continuous life evaluation of 5,000 hours generally.

Function Tester

Function Tester

The Function tester is configured to control status of automotive according to various conditions. This tester verifies that ECU performs the intended functions by implementing diverse signal inputs or environmental conditions on ECU.It is a system that tests operation characteristics and durability characteristics of ECUs by measuring communication and output signals.

Electrical Reliability Tester

Electrical Reliability Tester

The Electrical reliability tester operates which is connected to generators and batteries inside of the car. Electrical reliability conducts tests for the operation characteristics of ECUs under such conditions as generator voltage, battery voltage fluctuation, short-circuiting and disconnection of signal lines.

Outline of ECU Tester

Outline of ECU Tester

Environmental durability

Repeating the same signal input conditions by signal

processing of computer programs

Data monitoring and judgment

Monitoring and judging the measured values based on

the set criteria and recording the inspection process

Reducing human errors

Reducing errors significantly due to human factors with

product inspection function according to the

designated inspection method

CUSTOMER CENTER

We will listen carefully to our customers.

Corporate inquiry

Corporate inquiry